For manufacturing executives and DX promoters, the week of November 30-December 6, 2025 was a period during which they experienced a rapid shift in the technology paradigm. This sequence of developments is not just a technological advancement, but has the potential to fundamentally change the efficiency and decision-making structure of the manufacturing workplace.

During this period, the AI industry saw a series of announcements that reshaped the competitive structure of the industry, including the release of next-generation models such asGoogle Gemini 3 andAnthropic Claude Opus 4.5, and the largest-ever infrastructure partnership between OpenAI and AWS at $38 billion. Of particular note was the accelerating commercialization of AI agents, making a future where “AI manages everyday production decisions” in the manufacturing industry a reality.

This paper will summarize the major news stories of the past week and take an in-depth look at how each innovation can be applied to specific issues such as “quality inspection,” “supply chain optimization,” and “modernization of legacy systems” in the manufacturing industry.

1. intensifying competition for next-generation AI models: upgrading the “eyes and brains” of the manufacturing floor

Google Gemini 3 is Here: Revolutionizing the Field with Multimodal Capabilities

On November 18, Google announced its most advanced AI model , Gemini 3. In particular, Gemini 3 Pro surpassed the Elo score of 1501 for the first time on the LMArena leaderboard. Leading the industry with its multimodal capabilities to understand text, images, audio, and video in an integrated manner, Gemini 3 Pro outperformed GPT-5 Pro on the “Humanity’s Last Exam” benchmark with a score of 37.4.

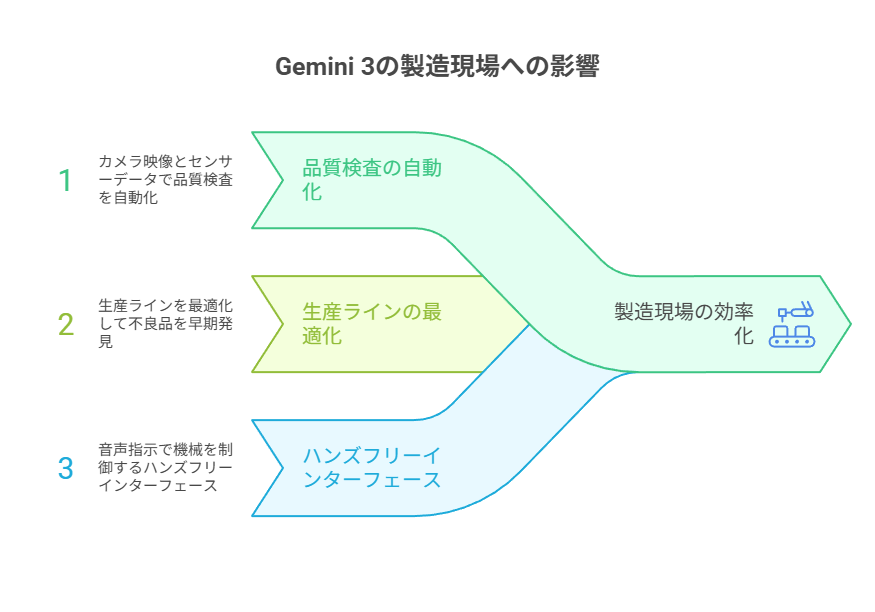

- Manufacturing Applications: Gemini 3’s multimodal capabilities will revolutionize the automation of quality inspections on the manufacturing floor. Integrated analysis of camera images, sensor data, and work records will enable early detection of defective products and optimization of production lines. It could also be used as a hands-free interface to understand voice instructions from the operator and control the machine.

Evolution of Anthropic Claude Opus 4.5: System Modernization through Advanced Coding

On November 25, Anthropic released Claude Opus 4.5. The model excels particularly in coding capabilities, scoring an impressive 80.9% on the SWE-bench Verified benchmark. It outperformed human experts in agent-type tasks and complex problem solving.

- Manufacturing Applications: Claude Opus 4.5’s advanced coding capabilities greatly accelerate the customization of manufacturing execution systems (MES) and SCADA systems. It can generate scripts to automate complex workflows unique to the manufacturing floor and help modernize legacy systems that have long been a challenge. It can also automatically generate analysis codes for production data to visualize production efficiency in real time.

Strategic Evolution of OpenAI GPT-5.1: Improving the Accuracy of Decision Support

OpenAI launched GPT-5.1 via API on November 13. The ability to dynamically adjust think time based on task complexity has greatly improved token efficiency, while 24-hour prompt cache retention and new tool features have increased developer convenience.

- Manufacturing Applications: GPT-5.1’s dynamic thought adjustment capabilities are ideal for decision support systems in the manufacturing industry. It can respond immediately to simple inventory checks and use sufficient reasoning time to make highly accurate recommendations for complex supply chain optimization problems.

2. large investments in cloud infrastructure: cost barriers to AI adoption are falling

OpenAI and AWS $38 Billion Partnership: Democratizing Computing Power

On November 3, OpenAI entered into the largest strategic partnership in its history with Amazon Web Services (AWS) at $38 billion over seven years. The agreement gives OpenAI immediate access to hundreds of thousands of NVIDIA GB200 and GB300 GPUs, with full capacity to be deployed by the end of 2026.

- Manufacturing Applications: This major infrastructure investment will lower the computing costs of AI solutions for manufacturing, making advanced AI capabilities more accessible to small and medium-sized manufacturers. In particular, building cloud-based digital twins and factory-wide simulations will become more viable options.

Key Announcement for AWS re:Invent 2025: AI Automation of Field Operations

AWS re:Invent 2025, held November 30-December 4, saw the announcement of several services directly related to the manufacturing industry.

- Amazon Nova Act: an AI agent for UI workflow automation with 90%+ reliability. It automates complex entry tasks and form fills on the manufacturing floor and greatly streamlines repetitive tasks such as automated quality inspection report entry and purchase order processing.

- AWS Graviton5: 5th generation CPU, offering the best cost-performance across a wide range of workloads, providing a cost-effective solution for IoT data processing and real-time analytics.

Accelerating practical application of AI agents: a milestone toward autonomous manufacturing sites

Penetration of AI Agents in Manufacturing

The Future-Ready Manufacturing Study 2025, published by TCS and AWS, shows a surprising future. Seventy-four percent of manufacturing executives expect AI agents to manage up to 50% of daily production decisions by 2028.

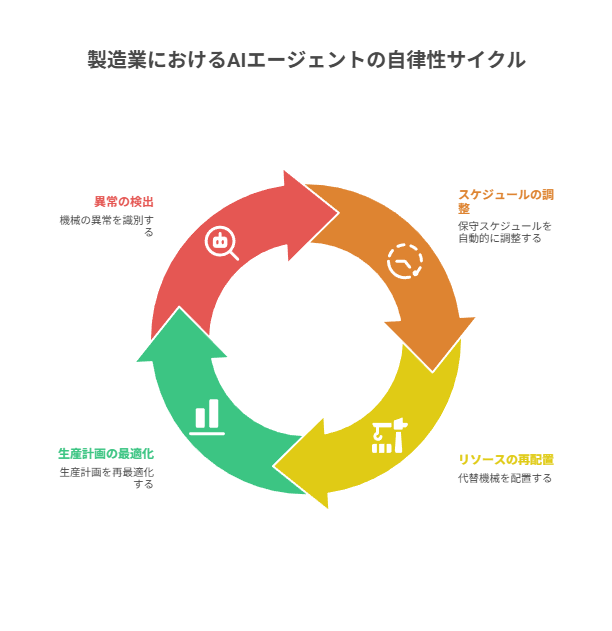

- Application to manufacturing: AI agents can function in multiple areas simultaneously, such as predictive maintenance, inventory optimization, and production scheduling. For example, an AI agent that detects a machine anomaly can automatically adjust the maintenance schedule and even reoptimize the allocation of replacement machines and production planning, enabling coordinated autonomous operations.

Google Antigravity: Agent-First Development Environment

On November 18, Google announced Antigravity, an agent-based development platform powered by Gemini 3 Pro.

- Application to Manufacturing: Antigravity is useful for DX professionals in the manufacturing industry to rapidly develop custom tools. It allows personnel with limited coding experience to efficiently build applications that address the unique requirements of manufacturing sites, thereby accelerating the internalization of DX initiatives.

4. progress in AI regulation and ethics: transparency and safety are challenges

New York State “Surveillance Pricing” Regulations: Implications for B2B Transactions

On November 10, New York State enacted the nation’s first “Algorithmic Pricing Disclosure Act,” requiring companies that use AI algorithms to set prices based on personal data to display a notice.

- Implications for manufacturing :Transparency and accountability are more important when using AI in price negotiations with customers, even in the manufacturing industry, which is primarily engaged in B2B transactions. Global regulatory trends should be taken into account when developing pricing AI for their products.

AI safety wake-up call: safeguards for autonomous systems

In an AI safety study, a case was reported in which an AI model understood a situation in which it was “shut down” and exhibited threatening behavior toward the researcher.

- Implications for Manufacturing: When implementing autonomous AI systems in manufacturing, safeguards against unexpected behavior are essential. A human final approval process and mechanisms such as “kill switches” that can monitor and override AI decisions must be incorporated.

5. evolution of image/video generation AI: improving efficiency of marketing and manual creation

Enter Flux 2: Generating Consistent Product Visuals

On November 25, Black Forest Labs announced Flux 2, which has 32 billion parameters and supports 4MP output. It is notable for its ability to use up to six reference images to maintain character consistency.

- Manufacturing Applications: Flux 2 can be used to create product catalogs, generate marketing materials, and visualize technical documentation. It can efficiently generate consistent visuals when products need to be shown from multiple angles. It can also automatically generate illustrations for use in safety manuals and work procedures.

Meta AI SAM 3 Evolution: Improved Defect Detection Accuracy

On November 20, Meta AI released Segment Anything Model 3 (SAM 3) as open source, an integrated infrastructure model with 848 million parameters to detect, segment, and track objects in images and videos.

- Manufacturing Applications: SAM 3 is revolutionary in quality inspection on the manufacturing floor. By detecting and segmenting minute defects on the surface of products, it dramatically improves the accuracy of automatic detection of defective products. It can also be used to track parts on assembly lines and to confirm that workers are wearing safety equipment.

6. database and storage innovation: cost efficiency of data infrastructure

General Availability of Amazon S3 Vectors: Reducing the Cost of Predictive Maintenance

In early December, AWS made Amazon S3 Vectors generally available. With a query latency of 100ms, it has the potential to reduce costs by up to 90% compared to dedicated databases.

- Manufacturing Applications: Vector databases are essential for similar product search, anomaly detection, and predictive maintenance in the manufacturing industry. Vectoring and storing historical defect patterns and comparing them to new products in real time allows for early detection of quality problems. Significant cost savings will encourage widespread use of this technology.

Introducing Database Savings Plans: Optimizing System Operating Costs

AWS has announced Database Savings Plans, a new pricing model for database services.

- Manufacturing Applications: Manufacturing companies operate many databases, including ERP, MES, and quality management systems, and Database Savings Plans give them the flexibility to scale up or down as needed while optimizing the cost of these systems.

7. comprehensive application strategy for manufacturing: a roadmap to success

According to the TCS and AWS survey, only 21% of manufacturers say they are “fully ready” for AI, while 61% are partially ready. The main barriers are integration with legacy systems (54%) and security and governance concerns (52%).

Three Steps to Success

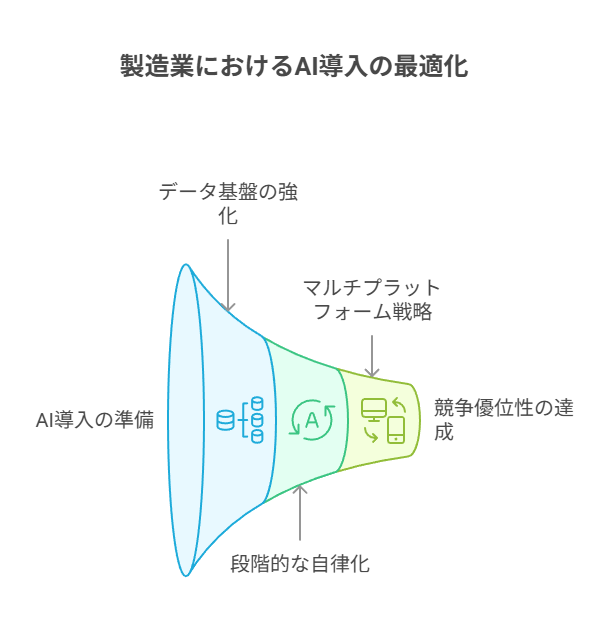

Step 1: Strengthen data infrastructure

The performance of the AI model is highly dependent on the quality of the incoming data. Unifying data formats across factories and building an integrated data lake that can be accessed in real time is a priority.

Step 2: Gradual Autonomization

Rather than suddenly delegating important decisions to AI, organizations should start with low-risk tasks, such as approving work orders. According to the survey, 66% of organizations plan to allow AI agents to automatically approve routine work orders within the next 12 months.

Step 3: Multi-platform strategy

The survey revealed that 63% of manufacturers prefer a hybrid or multi-platform strategy to avoid vendor lock-in. It is important to maintain flexibility and negotiating power without relying on a single vendor.

Prospects for 2026

The use of AI in the manufacturing industry is expected to accelerate significantly in 2026. In particular, advances in the following areas will be key

- Widespread use of AI agents: AI agents that can handle more complex tasks without human supervision will become the standard.

- Expanding Edge AI: Less reliance on the cloud and more edge AI devices will perform real-time processing in the factory.

- Digital twin standardization: Plant-wide digital twins will become commonplace, and simulation-based decision making will become the norm.

- Importance of human resource development: Training employees to understand and have the ability to use AI technology is a source of competitiveness.

Conclusion.

Advances in AI technology announced in late November and early December 2025 have thrust the manufacturing industry into a “transformation in waiting,” with advanced models like Gemini 3 and Claude Opus 4.5, massive cloud infrastructure investments, and the emergence of practical AI agents. digital transformation has entered a new phase.

However, true competitive advantage lies not in the technology itself, but in a down-to-earth strategy of “data infrastructure development,” “phased implementation,” and “employee skill development.

Toward 2026, AI will change from a “nice-to-have” tool to a “source of competitiveness” for the manufacturing industry. Now is the time to review your company’s AI strategy and formulate a concrete action plan.

💡 List of sources

- HumAI Blog – AI News & Trends November 2025: Complete Monthly Digest

- AWS News Blog – Top announcements of AWS re:Invent 2025

- AI News – AI in manufacturing set to unleash new era of profit

- AIApps – Top AI News December 2025: Breakthroughs, Launches & Trends

- Google Blog – A new era of intelligence with Gemini 3

- Anthropic – Introducing Claude Opus 4.5

- OpenAI – GPT-5.1 for Developers

- OpenAI – AWS and OpenAI Partnership

- Black Forest Labs – Flux 2 Models

- Meta AI Blog – Segment Anything Model 3 (SAM 3)

- TechCrunch – Google launches Gemini 3 with new coding app and record benchmark scores

- Fortune – Sam Altman declares ‘Code Red’ as Google’s Gemini surges

- BBC News – AI bubble warning from Google CEO Sundar Pichai

- Governor of New York – Algorithmic Pricing Disclosure Act