At the beginning of the year 2026, the artificial intelligence (AI) industry is at a new turning point. The series of news announcements from January 4-10 are of particular significance to the manufacturing industry. In this report, we summarize the major AI-related news of the past week and discuss its potential applications in the manufacturing industry.

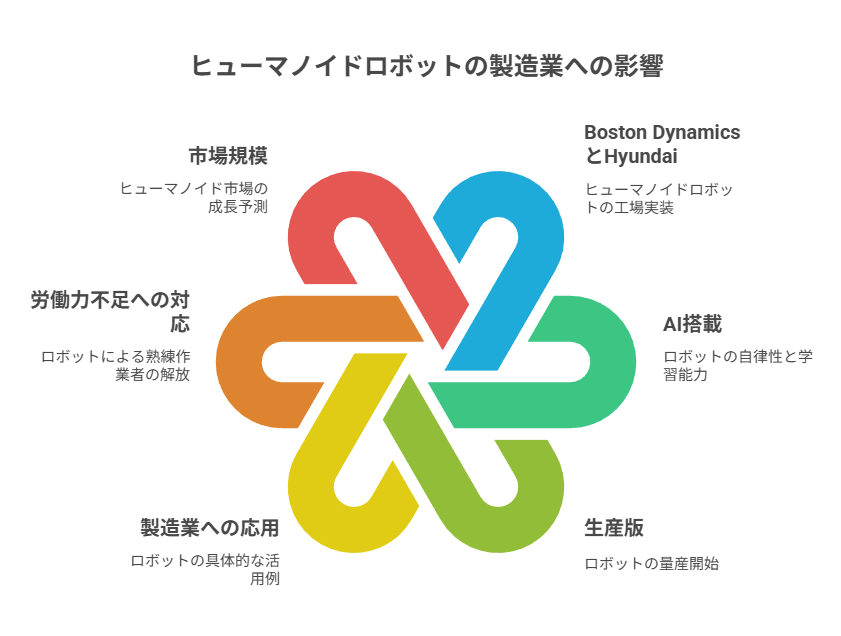

1. Boston Dynamics and Hyundai: Factory Implementation of Humanoid Robots a Reality

On January 4, 2026, CBS News’ “60 Minutes” reported what shocked the manufacturing industry: Boston Dynamics’ newest humanoid robot, Atlas, began its first field test at Hyundai’s plant near Savannah, Georgia.

Standing 5’9″ tall and weighing 200 pounds, Atlas is an AI-powered, fully electric robot that autonomously performs roof rack sorting tasks in a parts warehouse without human assistance. Notably, Atlas has the ability to “learn”: powered by Nvidia’s AI chip, Atlas can be remotely controlled using virtual reality and “motion capture learning,” which captures human movements, allowing more than 4,000 digital twins to spend six hours in a virtual environment The system has a mechanism whereby they undergo training and the learning results are shared with all Atlas robots.

At CES 2026, Boston Dynamics announced that it will immediately begin manufacturing a production version of Atlas. The company’s factory has a production capacity of 30,000 units per year, with actual deployments at Hyundai and Google DeepMind scheduled for 2026; Forbes reports that Boston Dynamics is “fully committed to production in 2026” and that Google Through a new AI partnership with DeepMind, the company plans to integrate Gemini Robotics’ AI infrastructure model into Atlas.

Manufacturing applications:

The factory implementation of Atlas is a “ChatGPT moment” for the use of humanoid robots in the manufacturing industry. Unlike conventional fixed industrial robots, humanoids can use existing work environments designed for humans. Goldman Sachs estimates that the humanoid market will reach $38 billion over the next decade.

However, as Robert Playter, CEO of Boston Dynamics, points out, these robots require “management, manufacturing, training, and maintenance” and do not completely eliminate the need for humans. Rather, they function as tools that free skilled workers from simple tasks and allow them to focus on higher value-added work in a manufacturing industry facing labor shortages.

2. physical AI from NVIDIA: from autonomous driving to manufacturing

On January 5, NVIDIA declared at CES 2026 that the “ChatGPT moment for physical AI has arrived” and announced a set of robot-specific chips and AI models available for free. Of particular interest are the following two platforms.

Alpamayo Autonomous Driving Platform: 10 billion-parameter Vision-Language-Action (VLA) model “Alpamayo 1” leverages Chain-of-Thought reasoning to handle complex driving scenarios. It is based on the Physical AI Open Dataset, which includes more than 1,700 hours of driving data and 310,895 clips collected from more than 2,500 cities in 25 countries, and has been selected by Mercedes-Benz for use in its CLA model.

Nemotron Speech ASR: Automatic speech recognition model for real-time applications, 10 times faster than previous systems. It is optimized for live captioning, voice assistants, in-car voice commands, etc. Bosch has already integrated it into its in-car command system.

Manufacturing applications:

The “Physical AI Factory” concept, announced through a partnership between NVIDIA and Siemens, represents the future of manufacturing. Integrating digital twin technology and AI models, the entire factory design and operation can be simulated and verified in a virtual environment prior to actual implementation. This will address the problem of skilled labor shortages while improving operational efficiency and supply chain resilience with AI companions. For example, factories will be able to adapt in real time to challenges such as weather disruptions and port delays.

LG Electronics’ smart home AI robot, LG CLOiD, also uses the NVIDIA Jetson Thor platform and is being tested in a virtual environment with NVIDIA Isaac Sim. NVIDIA CEO Jensen Huang said, “The physical world To learn common sense, three core computation systems are essential: training, reasoning, and simulation,” and this applies equally to the manufacturing floor.

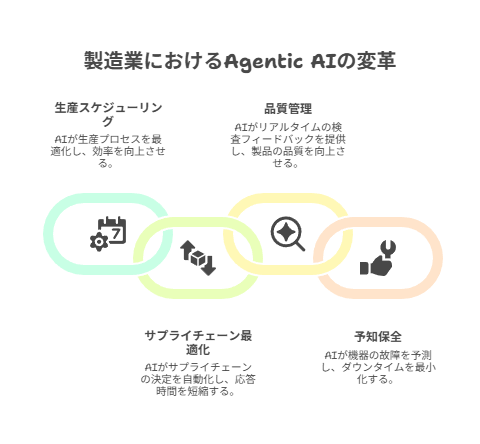

3. Agentic AI: Autonomous Agents Transforming Manufacturing Workflows

In January 2026, one of the hottest trends in the manufacturing industry is Agentic AI. This refers to autonomous AI systems that make decisions and perform complex tasks without human supervision. The market size is projected to grow from $5.2 billion in 2024 to $200 billion by 2034.

Deloitte’s 2026 Manufacturing Industry Outlook report, under “Smart Manufacturing and Operations,” clearly states that continued investment in Agentic AI will increase competitiveness and agility Agentic AI proactively plans manufacturing workflows and collaborates with human expertise in ways that guide critical decision making. Agentic AI actively plans manufacturing workflows and collaborates with human expertise in a way that guides critical decision making.

Plastics Today reports and analyzes that Agentic AI will play a key role as manufacturing evolves to meet increasingly complex demands. “What we consistently hear from our customers is that they need parts, but they want to reduce the steps from prototype to We need parts, but we want to reduce the number of steps from prototype to production,” he said, noting that Agentic AI will solve this challenge.

Manufacturing applications:

Agentic AI will transform manufacturing in the following areas

- Production Scheduling: IDC predicts that by 2026, more than 40% of manufacturers with production scheduling systems will upgrade to AI, and by 2029, 30% of factories will run automation on a centralized software-defined platform.

- Supply Chain Optimization: Danfoss used Agentic AI to automate 80% of transaction decisions, reducing customer response time from 42 hours to almost instantaneous.

- Quality control: AI agents provide real-time inspection feedback and guidance on manufacturability.

- Predictive maintenance: Predict equipment failures and minimize downtime.

Anil Jain, Global Managing Director of Google Cloud, stated that “2026 will be the year AI agents fundamentally reshape business.

4. introduction of a compact high-performance AI model: Falcon-H1R

The Falcon-H1R 7B, announced by the Technology Innovation Institute (TII) in January 2026, represents a new trend in AI models. With only 7 billion parameters, it is comparable in performance to a system seven times its own size.

TransformerMamba hybrid architecture and scored 88.1% on the AIME-24 math benchmark (outperforming Apriel 1.5’s 86.2% with 15 billion parameters); achieved 68.6% on the LCB v6 coding task, 32 billion parameters Qwen3 with 32 billion parameters by approximately 7 percentage points. Processing speeds of approximately 1,500 tokens per second per GPU were achieved with a batch size of 64.

Of note is the “DeepConf (Deep Think with Confidence)” feature, which filters out low-quality inferences during test-time scaling without additional training, ensuring more reliable output.

Manufacturing applications:

Compact, high-performance models like the Falcon-H1R are ideal for “edge AI” implementations on the manufacturing floor. Because they do not rely on the cloud and run on local devices in the factory, they have low latency and are energy efficient. They are promising for powering robots, autonomous vehicles, and edge computing solutions.

In the manufacturing industry, there are many situations where real-time decision making is required. Compared to large models, small language models (SLMs) are used for specific repetitive tasks and provide up to 1,030 times reduction in latency, energy, and computational efficiency. This provides significant benefits in terms of both cost savings and reduced environmental impact in production lines that operate 24 hours a day, 7 days a week.

5. GPT-5.2 of OpenAI: New Standard for Professional Tasks

OpenAI’s GPT-5.2, released on December 11, 2025, continues to be a hot topic in January 2026. It supports more advanced professional tasks and consistently outperforms GPT-4 in coding, STEM areas, and writing.

Of particular note is GPT-5.2-Codex, released on December 18, which is considered the most advanced agent-based coding model for professional software engineering and defensive cybersecurity. It features a longer context, improved tool use, large-scale refactoring, and improved Windows performance.

Also on January 7, ChatGPT Health was announced, offering a dedicated experience for health and wellness. The model output has been tested over 600,000 times in 30 focal areas and has been optimized for specific areas.

Manufacturing applications:

The advanced coding capabilities of GPT-5.2 will accelerate the digital transformation of the manufacturing industry. In particular, the following applications are expected

- Automated script generation: Streamlines programming of manufacturing execution systems (MES) and programmable logic controllers (PLC).

- Digital Twin Development: Assists in generating complex simulation code.

- Predictive Maintenance Algorithms: Develop custom algorithms to analyze sensor data and predict equipment failures.

- Cyber Security: Detect vulnerabilities in industrial control systems (ICS) and SCADA systems at manufacturing facilities and propose defensive measures.

The emergence of specialized AI models will enable manufacturing engineers to use AI as a partner to solve complex problems more quickly and accurately.

6. Meta: Strengthening AI Infrastructure with Nuclear Energy

On January 9, 2026, Meta announced that it has signed contracts with Vistra, TerraPower, and Oklo to secure up to 6.6 gigawatts of nuclear energy. This is to power the AI data center, specifically the Prometheus AI Supercluster in New Albany, Ohio.

Prometheus is expected to come online during 2026 and is expected to consume vast amounts of electricity.

Manufacturing applications:

Meta’s move highlights the energy challenges faced by AI-driven manufacturing: AI-driven smart factories require more power than ever before to process large amounts of sensor data in real time and run complex simulations.

Manufacturers should consider the following measures

- Invest in renewable energy: Secure clean energy sources such as solar, wind, and nuclear to stabilize long-term energy costs.

- Optimize energy efficiency: Reduce energy consumption by leveraging smaller AI models and edge computing.

- Carbon Neutral Goal: Minimize the environmental impact of AI operations to meet ESG (Environmental, Social, and Governance) requirements.

Investing in nuclear energy is an important step for the sustainable growth of AI, and the same strategic decisions must be made by the manufacturing industry.

7. The Economist: “ChatGPT Moment” in the Manufacturing Industry

A January 7 article in The Economist, “The ‘ChatGPT moment’ has arrived for manufacturing,” symbolizes a turning point in the manufacturing industry. The article begins with General Motors Chairman Roger Smith in 1985, “impressed by watching a robot pick up an egg,” and contrasts its subsequent failure with its current success.

According to the International Federation of Robotics (IFR), there were approximately 4.7 million industrial robots in operation worldwide as of 2024, just 177 per 10,000 manufacturing workers. Annual installations are projected to increase from 542,000 in 2024 to 619,000 in 2026.

Roland Berger consultants forecast that sales of industrial automation equipment will rise from 1-2% growth in 2025 to 3-4% in 2026, adjusted for inflation, and then record 6-7% growth for the period through 2030.

Transformation to manufacturing:

The Economist presents Siemens’ Bavarian plants in Amberg and Erlangen as examples of the factories of the future: the Amberg plant produces about 20 times as much as it did when it opened in 1989, while the number of workers is about the same. Robotic arms manufactured by Universal Robots perform welding, cutting, assembly, and inspection.

At the Erlangen plant, autonomous carts are equipped with screens and move around the production site, with humans and robots working together at each station.

The article emphasizes that software evolution is equally important as hardware evolution:

- Programmability: Robots once locked into one task can now be reprogrammed for another with code adjustments.

- Digital twin: 2-D paper-based blueprints are replaced by precise 3-D reproductions, making product design and manufacturing process testing faster and cheaper Siemens will acquire Altair in 2024 for $10 billion, its largest acquisition ever, and software now accounts for one-third of the company’s industrial automation division sales. 1 percent of the company’s industrial automation sales.

- Bridging the Sim-to-Real Gap: Until now, simulations have broken down when lighting or object geometry changes, but large-scale AI models trained with vast amounts of data from sensors and cameras are solving this problem.

As a result, factories could become not just automated, but “autonomous,” as Tessa Myers of Rockwell Automation puts it, “Imagine a factory where machines anticipate needs, materials move seamlessly without human intervention, and production lines adapt in real time to changes in demand and disruptions. I want you to imagine it,” she stated.

Furthermore, if each robot can perform a wide range of tasks, factory designs will no longer need to be centered on long assembly lines. Combined with lower hardware costs, this would allow many companies to distribute manufacturing across a network of smaller factories. This would bring benefits in terms of proximity to urban areas (easier worker retention), proximity to customers (considering tariff continuity), and risk diversification (failure of a single factory would not be a crisis).

A Comprehensive Look at Manufacturing: Practical Strategies for 2026

The above seven trends reveal the strategies that manufacturers should adopt in 2026 and beyond.

Short-term strategy (within 2026)

- Initiate a pilot program: test collaborative robots such as Boston Dynamics and Universal Robots in a limited environment to measure ROI (return on investment).

- AI Skills Training: Implement training programs to make the existing workforce proficient in the use of AI tools. A hybrid “human + AI” model is most effective.

- Implement a digital twin: Create a digital replica of the production line using solutions such as Siemens. Test changes in a virtual environment before implementation.

- Agentic AI pilot: Testing AI agents in specific areas such as production scheduling, inventory control, and quality control.

Medium-term strategy (2026-2028)

- Phased introduction of humanoid robots: By 2028, Hyundai plans to deploy humanoid robots in its factories. With a similar timeline, replacement will begin with repetitive and physically demanding tasks.

- AI-native factory design: adopt designs that assume AI and robot integration in new factories and during renovations. Also consider small, distributed, networked factories.

- Build edge AI infrastructure: Build an edge AI system that reduces cloud dependence and enables real-time processing in the factory.

- Strengthen supply chain resiliency: AI-driven supply chain management to increase adaptability to geopolitical risks, tariff changes, and material price volatility.

Long-term strategy (2028-2034)

- Transition to fully autonomous factories: Aim to achieve “lights-out” operation (no humans, only machines). However, humans will still be needed for monitoring, maintenance, and strategic decision making.

- Integrating Sustainability: Investments in nuclear and renewable energy to make AI infrastructure carbon neutral.

- Ensure global competitiveness: China has a mission to win the robotics race at the national level. Continuous investment and innovation are essential to maintain the technological lead.

- Explore new business models: aftermarket services, subscription-based manufacturing, mass customization, and other new revenue streams in the AI era.

Importance of Human Resource Strategies

Dave Evans, CEO of Fictivs, emphasizes that “the organizations that win through all of this are the ones that combine these technologies with an adaptive, digitally savvy workforce. “While AI can flag and suggest process options, it is the experienced manufacturing engineer who makes the delicate tradeoffs between cost, tolerances, finish, and risk. It is the experienced manufacturing engineer who makes the tradeoffs.

The manufacturing industry should invest in the development of the following human resources

- AI Literacy: All employees understand basic AI concepts.

- Data Scientist: an expert in analyzing manufacturing data and optimizing AI models.

- Robotics Technician: responsible for maintenance and programming of humanoid and cooperative robots.

- Cyber Security Expert: As AI systems and IoT devices increase, so do security risks.

Risks and Challenges

- Investment Cost: Initial investment in AI technology and robotics is high; ROI should be carefully calculated and phased implementation is recommended.

- Technological maturity: Humanoid robots are not yet capable of performing everyday tasks such as “getting dressed” or “carrying coffee while walking. Do not expect too much.

- Workforce disruption: loss of some jobs due to robotization is inevitable. Retraining programs and social safety nets must be established.

- Data Privacy and Security: The vast amount of data collected by AI systems can be a potential target for cyber attacks.

- The “2026 Problem”: As reported by the Japanese media, it has been pointed out that generative AI may run out of high-quality data on which to learn by the end of 2026. This means that AI performance improvement will reach its limit, and new learning methods such as “synthetic data” and “reinforcement learning” will become important.

Conclusion: Manufacturing Evolves with AI

The rapid evolution of AI technology and its penetration into manufacturing was evident in just one week in January 2026: Boston Dynamics’ Atlas, NVIDIA’s Physical AI, the rise of Agentic AI, small high-performance models, OpenAI’s GPT-5.2, Meta’s nuclear energy investments, and the “ChatGPT moment” noted by The Economist – all point to a fundamental transformation in manufacturing.

As Google Cloud’s Anil Jain stated, “2026 is the year AI agents will fundamentally reshape business,” and NVIDIA’s Jensen Huang’s declaration that “the ChatGPT moment of physical AI has arrived” is not mere hyperbole.

Manufacturers need to start acting now to catch this wave. But technology adoption alone is not enough. Human expertise, creativity, and ethical judgment remain essential; AI will not replace humans, but will be a powerful tool to augment them and create greater added value.

The “factory of the future” dreamed up by GM’s Roger Smith in 1985 failed, but now, in 2026, technology has finally reached a point where that dream can be realized. The key to success this time, however, lies not in simply implementing the technology, but in creating a new manufacturing ecosystem in which humans, AI, robots, and workers work together.

The future of manufacturing is bright. The year 2026 will go down in history as the year that opened the door to that future.

Source List

- CBS News (January 4, 2026). “Boston Dynamics’ AI-powered humanoid robot is learning to work in a factory”. https://www.cbsnews.com/news/boston-dynamics-ai-powered-humanoid-robot-learning-factory-work-60-minutes-transcript/

- Boston Dynamics (2026). “Boston Dynamics Unveils New Atlas Robot to Revolutionize Industry”. https://bostondynamics.com/blog/boston-dynamics-unveils-new-atlas-robot-to-revolutionize-industry/

- Boston Dynamics (2026). “Boston Dynamics & Google DeepMind Form New AI Partnership”. https://bostondynamics.com/blog/boston-dynamics-google-deepmind-form-new-ai-partnership/

- Forbes (January 6, 2026). “Atlas Humanoid Robots Production ‘Fully Committed’ For 2026, Factory Will Build 30,000 Per Year”. https://www.forbes.com/sites/johnkoetsier/2026/01/06/atlas-humanoid-robots-production-fully-committed-for-2026-factory-will-build-30000-per-year/

- BBC News (January 2026). “Car giant Hyundai to use human-like robots in factories”. https://www.bbc.com/news/articles/cvgjm5x54ldo

- AI Apps (January 8, 2026). “Top AI News for January 2026: Breakthroughs, Launches & Trends”. https://www.aiapps.com/blog/ai-news-january-2026-breakthroughs-launches-trends/

- The Economist (January 7, 2026). “The ‘ChatGPT moment’ has arrived for manufacturing”. https://www.economist.com/interactive/business/2026/01/07/the-chatgpt-moment-has-arrived-for-manufacturing

- Deloitte (November 13, 2025). “2026 Manufacturing Industry Outlook”. https://www.deloitte.com/us/en/insights/industry/manufacturing-industrial-products/manufacturing-industry-outlook.html

- Plastics Today (January 5, 2026). “AI and Resilience to Redefine Manufacturing in 2026”. https://www.plasticstoday.com/business/ai-and-resilience-to-redefine-manufacturing-in-2026

- Meta (January 9, 2026). “Meta Announces Nuclear Energy Projects, Unlocking Up to 6.6 GW to Power American Leadership in AI Innovation”. https://about.fb.com/news/2026/01/meta-nuclear-energy-projects-power-american-ai-leadership/

- CNBC (January 9, 2026). “Meta signs nuclear energy deals to power Prometheus AI supercluster”. https://www.cnbc.com/2026/01/09/meta-signs-nuclear-energy-deals-to-power-prometheus-ai-supercluster.html

- OpenAI (December 11, 2025). “Introducing GPT-5.2”. https://openai.com/index/introducing-gpt-5-2/

- OpenAI (December 18, 2025). “Introducing GPT-5.2-Codex”. https://openai.com/index/introducing-gpt-5-2-codex/

- OpenAI (January 7, 2026). “Introducing ChatGPT Health”. https://openai.com/index/introducing-chatgpt-health/

- Manufacturing Dive (January 8, 2026). “5 manufacturing trends to watch in 2026”. https://www.manufacturingdive.com/news/5-trends-watch-2026-tariffs-uncertainty-ai-workforce-chemical-investments/809109/

- Forbes (December 22, 2025). “10 AI Predictions For 2026”. https://www.forbes.com/sites/robtoews/2025/12/22/10-ai-predictions-for-2026/

- Diamond Online (January 10, 2026). “What is AI’s ‘2026 Problem’: Difficulty Adding Data, Performance Improvements About to Limit?” . https://diamond.jp/articles/-/381058

- Reuters (January 8, 2026). “Musk’s xAI to invest over $20 billion in Mississippi data center”. https://jp.reuters.com/markets/bonds/MR3V5DY7RJMJTH25735PEN7DNY-2026-01-09/

- ITmedia MONOist (January 7, 2026). “‘Physical AI’ Heats Up at CES 2026, Breaking Free of Buzzwords and Going Full-Scale”. https://monoist.itmedia.co.jp/mn/articles/2601/07/news056.html

- Yahoo! News Japan (January 6, 2026). “‘2026 is the Year of the Singularity’ Tech Giants Predict the Future of AI”. https://news.yahoo.co.jp/articles/652fcb12bfaf3a8f3b66a78bd28ee857d2976ede