The artificial intelligence sector experienced multiple significant announcements and market upheavals this week, and the series of events that unfolded between February 8 and 14 suggest a tipping point in the evolution of AI technology from a mere tool to an autonomous worker. Particularly in the manufacturing sector, these innovations are beginning to have a tangible impact on the production floor, and a detailed analysis of this week’s developments will provide useful insights for future strategic planning.

1. evolution of AI model: focus on agent functions

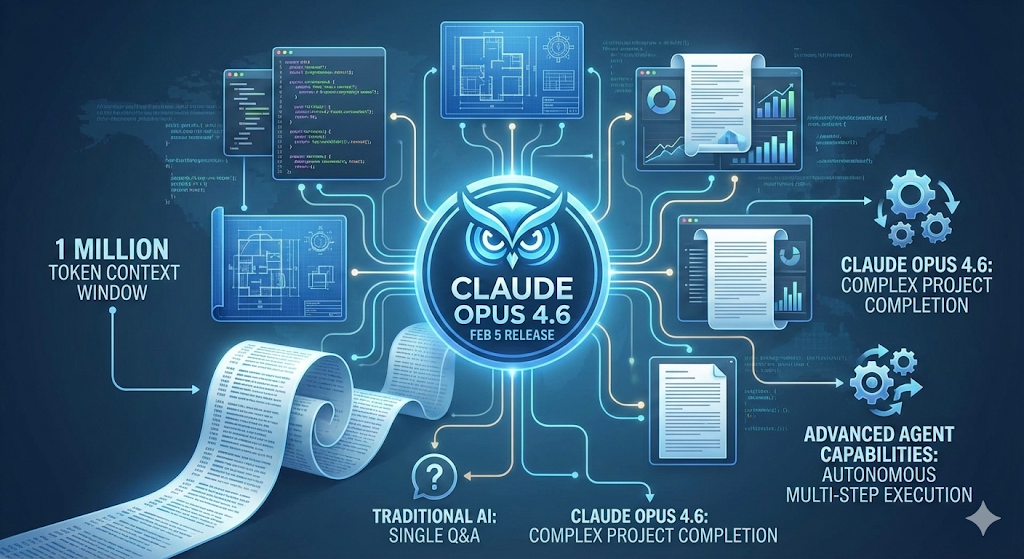

Anthropic Claude Opus 4.6 is now available

On February 5, Anthropic officially released Claude Opus 4.6. This model features a 1 million token context window and greatly enhanced “agent capabilities” for long-term tasks. Whereas traditional AI is limited to one-shot question-answering, Claude Opus 4.6 can automatically decompose complex projects into parallel subtasks and execute them autonomously over multiple steps.

Manufacturing Applications:

In the manufacturing industry, complex workflows across multiple systems, from production planning to quality control to supply chain optimization, exist on a daily basis, and an agent-based AI like Claude Opus 4.6 could manage these processes in an integrated manner, for example from forecasting production delays to alternative suppliers, and rescheduling.

MiniMax low-cost model

Chinese startup MiniMax has released two new language models, M2.5 and M2.5 Lightning. Notably, they achieve the same level of performance at one-twentieth the cost of Claude Opus 4.6, employing a Mixture of Experts architecture to achieve dramatic cost savings by activating only the parameters needed for each task.

Manufacturing Applications:

The cost of implementing AI has been a major barrier for small and medium-sized manufacturing companies, and the advent of low-cost models such as MiniMax makes it possible to have multiple AI agents running continuously for as little as $10,000 per year. This means that for applications such as quality inspection automation and maintenance prediction, it is a realistic option for SMEs.

2. unprecedented investment in AI infrastructure: $650 billion impact

This week, four major tech companies-Google, Amazon, Meta, and Microsoft-announced the largest capital spending plan in history , totaling approximately $650 billion in AI infrastructure investments for 2026, with Amazon alone planning $200 billion and Google between $175 billion and $185 billion dollars, a staggering increase of approximately 67% from the $381 billion planned for 2025.

However, after the announcement of this massive investment, the market capitalization of the four companies decreased by a combined total of more than $950 billion. Investors are skeptical that the returns will be commensurate with this massive investment.

Implications for Manufacturing:

This race for investment will have two important impacts on the manufacturing AI deployment environment. First, the accelerating performance and declining cost of cloud-based AI services will make it easier for manufacturers to access advanced AI capabilities. Second, increased competition from large tech companies will spur the development of specialized AI solutions for the manufacturing industry.

However, short-term market instability also represents an opportunity for manufacturing companies with a long-term AI strategy. By investing upfront while competitors are taking a wait-and-see approach, they may be able to establish a technological advantage.

3. self-validating AI: solving the error accumulation problem

One of the most important breakthroughs in AI development in 2026 is the ability to self-verify. Traditionally, when an AI agent performs a multi-step task, errors accumulate along the way and the final output is unreliable.

The new generation of AI systems have internal feedback loops that can autonomously verify the accuracy of their own work and correct errors. This enables reliable execution of complex workflows without human supervision.

Application to manufacturing:

In manufacturing, multiple processes proceed in a chain of events, such as production planning, inventory control, and quality assurance. With conventional AI systems, small errors at each step can accumulate and eventually cause major problems. AI with its self-verification function automatically establishes checkpoints at each step of the process to detect and correct anomalies, thereby greatly improving the reliability of the entire production line.

Specifically, in predicting parts shortages, the AI can evaluate its own prediction accuracy, and if there is a high degree of uncertainty, it can refer to multiple data sources for verification.

4. current status of AI implementation in the manufacturing industry: gap between expectations and readiness

A survey of 300 manufacturing professionals conducted by Redwood Software found that while 98% of manufacturing companies are considering or are considering AI-driven automation, **only 20%** say they are ready to use it on a large scale.

Major Findings:.

- 70% of manufacturing companies have automated less than 50% of their core operations

- 60% reduced unplanned downtime by 26% or more through automation

- 78% of critical data transfers are not automated, limiting real-time decision making

- Only 40% of exception handling is automated

- Inventory turnover remains difficult to improve

Challenges facing manufacturing:

Many manufacturing companies automate tasks and processes within individual systems, but the workflow, data flow, and exception handling between systems remains fragmented and manual. no matter how good the AI model is, as long as there is this friction in the execution pipeline, scale cannot scale.

Kevin Greene, CEO of Redwood Software, stated. “Manufacturers are not failing to automate; they are reaching the limits of siloed execution. Without an orchestration infrastructure that integrates the entire system, AI cannot effectively scale.”

5. 5 measurable trends in manufacturing AI use in 2026

According to InPixon’s analysis, manufacturing AI in 2026 is moving “from hype to pragmatism,” with the following five measurable trends identified

Trend 1: Agent AI for Proactive Process Control

While traditional AI only predicts and warns of problems, agent AI in 2026 is evolving from analysis to initiating action. The key is not unlimited autonomy, but control within predefined guardrails, approvals, and escalation paths.

Metrics: time from first alert to fix, reduction of unplanned outages, time to avoid line starvation

A real-world example from a manufacturing site:

If the system detects that the kitting buffer will be empty within 2 hours, it will not just issue a warning, but will combine real-time location information (forklift, kit, WIP, obstacle locations) with process logic (priorities, orders, constraints) to generate a recommendation for the next transport job re Generate specific decision suggestions such as routing, sequence changes to avoid line starvation, or issuing a maintenance ticket if a critical forklift is stuck.

Trend 2: Capacity and Bottleneck Optimization with AI

While many teams still plan capacity a posteriori, 2026 sees a shift to live context-based capacity control, where AI connects process data and real-time signals, including location data, to not only detect bottlenecks but also treat them as managed conditions.

Metrics: latency at constraint point, WIP to throughput conversion rate, shift ratio of stable flows vs. firefighting activity

Real-world example from a manufacturing site:

If WIP accumulates in front of Station B and there is idle time at Station D, the AI will distinguish causes: replenishment delays, misplaced transport assets, blocked handoff areas, extended inspection dwell time, etc. As a result, specific recommendations are provided, such as order re-prioritization, sequence adjustments, triggering targeted replenishment, and pressure relief with alternate routes or buffers.

Trend 3: AI for schedule compliance and OTD protection

In 2026, AI is shifting from “delay reporting” to “in-flight schedule protection”; ERP and MES show what should be there, but RTLS tells what is really going on: where is the WIP, has the kit actually arrived at the use location, are transportation assets really available, in real time where the flow is impeded.

Metrics: schedule compliance rate, number of hours of early warning, number of recovery orders per shift

A real-world example from manufacturing:

AI detects risk before orders are delayed. System status may still look fine, but execution signals tell a different story: WIP not working, kitting not complete despite being “picked,” congestion in handoff zone, staging blocked, wrong variant placed in buffer AI will not only flag ” risk” flagging as well as translating it into minimal action to protect the delivery.

Trend 4: Dynamic Fleet and Yard Management

In 2026, AI will become more practical in dispatch operations. It will use real-time location data to dynamically assign tasks, adapt routes, and reduce congestion early before it cascades into production line stoppages or starvation.

Metrics: empty run ratio, handoff dwell time, on-time replenishment rate, congested minutes per shift, true utilization by asset type

Trend 5: Human-centric AI

Many errors are not caused by a lack of skills, but by the realities of daily work such as context switching, time pressure, interruptions, media breaks, etc. The opportunity in 2026 is not “more information” but to provide the proper instructions needed at the moment of work.

Metrics: first-time pass rate, rework loops per shift, new operator proficiency time, “missing step” events detected at the line end vs. early detection

Real-world example from a manufacturing site:

An operator is working at station 4 and the current MES order requires step 3, which includes checkpoints and minimum inspection dwell time. The system automatically recognizes the context and displays the correct instructions. If sequence or dwell time requirements are not met, the system alerts the operator and provides an easy way to request assistance.

6. english becomes the hottest new programming language

AI coding capabilities provide an important bridge from the statistical, non-deterministic LLM world to the deterministic, symbolic logic computer world. This opens a new era of programming in English.

By 2026, the bottleneck in building new products will no longer be the ability to write code, but the ability to creatively shape the product itself. This shift will democratize software development and increase the number of creators capable of building applications tenfold, enabling more high-value, creative work.

Manufacturing Applications:

Manufacturing engineers and process improvement personnel will be able to create custom tools and dashboards in natural language without programming expertise. For example, simply instruct them to “create a report that analyzes defect rates by product line for the past three months and correlates them with specific component suppliers,” and the AI will generate and execute the necessary code.

7. open source model breaks the monopoly of the AI giants

By 2026, the power of foundational models will no longer be limited to a handful of companies. The biggest breakthroughs are occurring in the post-training phase, where models are refined with specialized data. This change will enable a wave of open source models that can be customized and fine-tuned for specific applications.

Implications for manufacturing:

Manufacturing companies can develop specialized models trained on their own production data instead of relying on generic models from large tech companies. For example, they can build models trained to predict the quality of specific materials or the optimization parameters of unique production equipment. This ensures data sovereignty and privacy while maintaining competitive advantage.

8. regulatory and ethical issues of AI

Non-participation in military AI declaration

On February 5, at the International Summit on Responsible Military AI (REAIM), major countries, including the United States and China, refused to sign a joint declaration on responsible AI deployment in the military domain. This reflects geopolitical tensions in the establishment of global norms on autonomous systems and human surveillance.

Enhanced policing of AI-generated content

On February 5, UNICEF called for criminal penalties for AI-generated content depicting child sexual abuse. In response to the surge in manipulated images, including deep fakes, we advocate robust detection, safety by design, and strict moderation across platforms.

Implications for Manufacturing:

These regulatory developments may have implications for the use of AI in manufacturing. In particular, employee oversight, data privacy, and transparency and accountability in AI decision making will be important topics. Manufacturing companies will need to establish ethical guidelines and governance frameworks from the early stages of AI implementation.

9. monetization of AI: emergence of advertising models

In early February, OpenAI began testing ads for free ChatGPT users and subscribers to the $8/month Go plan. Ads are targeted based on conversational context, previous ad interactions, and aggregate performance data. The program is being rolled out in the coming months.

Implications for Manufacturing:

The evolution of AI platforms as an advertising medium opens up new options for manufacturing marketing strategies: in B2B manufacturing, when procurement professionals and engineers use AI chatbots to search for parts and equipment, the right product information at the right time This could be done using AI chatbots.

10. manufacturing ai strategy 2026: a practical approach

Start small

Forbes analysis shows that AI strategies in manufacturing are most effective with a “problem-driven, solution-following” approach; AI tools such as ChatGPT and Perplexity have already penetrated the manufacturing industry, but the potential of AI goes far beyond these generic LLMs.

Recommended approach: (1)

- Identify constraints: identify areas where decisions are currently being made without sufficient information

- Small-scale validation: choose one flow (material replenishment, constrained area, handoff bottleneck) and measure baseline for 2-3 weeks

- Set guardrails: clearly define normal conditions, exceptions, allowed actions, and escalation paths

- Short-term validation cycle: compare before and after improvements and measure with clear KPIs

Ownership and Governance

For an AI to actually work, it must

- Clear process definition: what is deviation, what is “normal,” and which actions are allowed

- Ownership: who owns data quality, automation approvals, and success measurement

- Controlled automation: Agent AI only works with clear rules, approvals, and escalation paths

- Pre-start baseline metrics: downtime minutes, search time, dwell time, disposal, rework, WIP, throughput

Conclusion: The Year of Utilitarianism, 2026

The year 2026 will be remembered as the year AI moves from hype to pragmatism. The race to build large-scale models will slow down, and instead practical breakthroughs such as self-validation, improved memory, and agent interoperability will dominate.

For manufacturers, this shift represents a tremendous opportunity. With technology barriers falling, costs being reduced, and a focus on measurable results, manufacturing companies can deploy targeted AI solutions to specific business challenges.

The key to success, however, lies not in the technology itself, but in the implementation approach. Integrating fragmented systems in orchestration, supporting decision-making in real-time context, and providing autonomy within clear guardrails – this is the winning formula for 2026.

With 98% of manufacturing companies considering AI, the differentiator is not speed of adoption, but strategic clarity, measurement discipline, and governance. Don’t be fooled by the hype, start small, measure, learn, and scale – the companies that adhere to these principles will lead manufacturing in the AI era.

Source List

- AI Update, February 13, 2026: AI News and Views From the Past Week – Marketing Profs

https://www.marketingprofs.com/opinions/2026/54304/ai-update- february-13-2026-ai-news-and-views-from-the-past-week - AI Strategy For Manufacturers In 2026 – Forbes

https://www.forbes.com/sites/ethankarp/2026/02/09/ai-strategy-for-manufacturers-in-2026/ - 6 AI breakthroughs that will define 2026 – InfoWorld

https://www.infoworld.com/article/4108092/6-ai-breakthroughs-that-will-define-2026. html - AI by AI Weekly Top 5: February 2 – 8, 2026 – Champaign Magazine

https://champaignmagazine.com/2026/02/08/ai-by-ai-weekly-top-5- february-2-8-2026/ - Manufacturing AI And Automation Outlook 2026 – Redwood Software

https://www.redwood.com/press-releases/manufacturing-ai-and-automation- outlook-2026-98-of-manufacturers-exploring-ai-but-only-20-fully-prepared/ - 5 AI Trends in Manufacturing You Can Actually Measure in 2026 – InPixon

https://www.inpixon.com/blog/ai-manufacturing-trends-you-can-measure- 2026 - Claude Opus 4.6 Official Announcement – Anthropic

https://www.anthropic.com/news/claude-opus-4-6 - Big Tech AI Spending Analysis – Bloomberg

https://www.bloomberg.com/news/articles/2026-02-06/how-much-is-big-tech-spending-on-ai- computing - Market Reaction to AI Infrastructure Spending – Reuters

https://www.reuters.com/business/retail-consumer/anthropic-releases-ai-upgrade- market-punishes-software-stocks-2026-02-05/ - US, China opt out of joint declaration on AI use in military – Reuters

https://www.reuters.com/business/aerospace-defense/us-china-opt-out-joint -declaration-ai-use-military-2026-02-05/ - UNICEF calls for criminalization of AI content depicting child sex abuse – Reuters

https://www.reuters.com/legal/government/unicef-calls- criminalization-ai-content-depicting-child-sex-abuse-2026-02-05/ - ChatGPT rolls out ads – TechCrunch

https://techcrunch.com/2026/02/09/chatgpt-rolls-out-ads/