As the global AI competition accelerates, the first week of February 2026 saw a series of important innovations and business developments that will shape the future of manufacturing. What became clear during the week was the fact that AI is clearly moving from the “experimental phase” to the “implementation phase.”

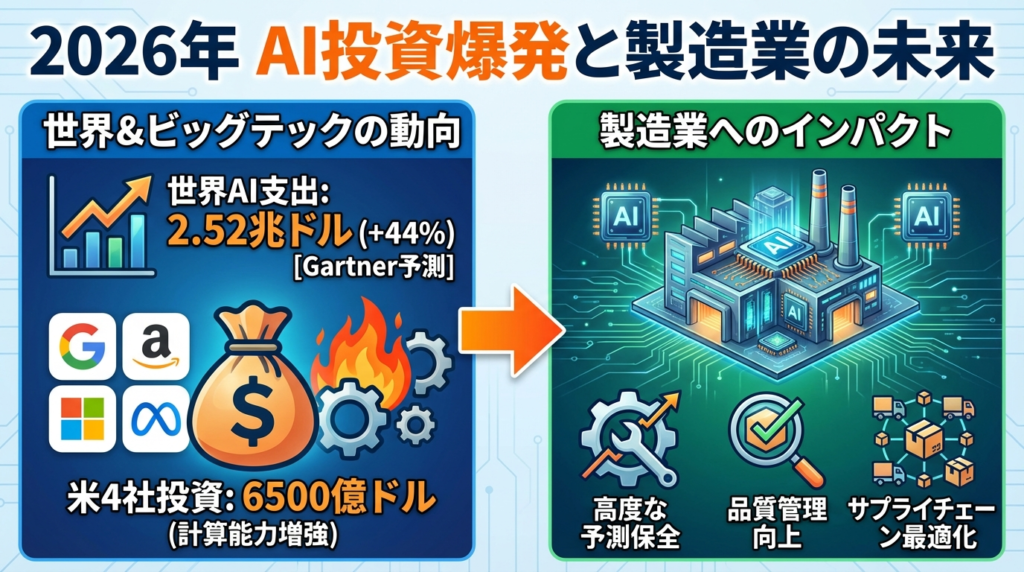

Explosive expansion of AI infrastructure investment

AI-related spending in 2026 is expected to reach $2.52 trillion globally, a staggering 44% growth over the previous year, according to Gartner’s projections. Of particular note are the massive investment plans announced by U.S. big tech over the past week.

On February 4, Google announced capital expenditures for 2026 in the range of $175 billion to $185 billion. This is the largest investment in the company’s history, primarily to increase AI compute capacity for Google DeepMind and to meet growing demand from cloud customers. This is a testament to the intensity of the AI competition.

This massive investment has important implications for the manufacturing industry, as increased AI computing power will dramatically improve the accuracy and processing speed of AI models used in manufacturing, enabling more advanced predictive maintenance, quality control, and supply chain optimization.

Evolution of Coding AI: The Emergence of GPT-5.3-Codex

On February 5, OpenAI announced the GPT-5.3-Codex. This is the most advanced agent-based coding model the company has developed, and it is worth noting that “the model contributed to its own development. The development team itself used an early version to debug training, manage deployments, and diagnose test results.

GPT-5.3-Codex achieved industry-leading performance on SWE-Bench Pro, a real-world assessment of software engineering, with a score of 56.8%. It also achieved a high performance of 77.6% on cybersecurity-related tasks.

As applied to the manufacturing industry, this model can be used to customize production management systems, develop PLM (Product Lifecycle Management) systems, and automatically generate software to process IoT sensor data. In particular, it has the potential to significantly shorten the development time for custom software that addresses the unique and complex requirements of manufacturing sites.

SpaceX and xAI Integration by Elon Musk

On February 2, Elon Musk announced that space firm SpaceX has acquired AI firm xAI and will merge the two companies Musk said, “In the long run, space-based AI is the only way to scale. Space will always be full of sunlight,” and predicts that within two to three years, space-based AI computation will be the least expensive.

The integration is part of a grand vision that also includes satellite communications company Starlink and social media company X. For manufacturers, it could revolutionize future global supply chain management and real-time communications infrastructure with remote factories.

Physical AI and the Rise of Humanoid Robots

Most notable in the first week of February 2026 was the commercial deployment of “physical AI” in full swing, as Nvidia CEO Jensen Huang declared at CES 2026, “The ChatGPT moment of physical AI has arrived,” and the robotics field has reached a tipping point It is.

Boston Dynamics and Google DeepMind Partnership

On February 3, Boston Dynamics announced a strategic partnership with Google DeepMind. The collaboration will integrate the Gemini Robotics AI model developed by Google DeepMind into Boston Dynamics’ next-generation humanoid robot, Atlas.

Atlas has 360-degree rotational joints, giving it greater flexibility than a human. It can lift heavy objects, adapt to dynamic environments, and work autonomously with minimal supervision. The company has announced that it will invest $26 billion to build a new plant capable of producing 30,000 robots per year.

Rapid Growth of the Humanoid Robotics Market

According to a Deloitte survey, 58% of more than 3,200 global business leaders are currently using some form of physical AI, and this figure is expected to reach 80% in the next two years.Tesla, Boston Dynamics, Figure AI, and others are leading the development of general purpose humanoid robots are leading the way, with applications in the defense, power, data center, and heavy equipment industries.

However, as Andy Lonsberry, co-founder of Path Robotics, points out, there is still a challenge: “A demo that works 70% of the time is not good enough for the manufacturing industry; you need 99% or better reliability.” Unplanned downtime can cost a company millions of dollars, so a cautious approach to implementation is required.

The Actual Situation of AI Introduction in the Manufacturing Industry

Rootstock Software’s January 2026 State of Manufacturing Technology Survey reveals the state of AI adoption in the manufacturing industry. The survey of digital transformation leaders from 520 medium to large manufacturing companies in North America, Europe, and Asia yielded the following key findings

Widespread adoption of AI and transition to operations

Ninety-four percent of those surveyed reported using AI in some form. The most significant growth was seen in predictive AI (up 12 points to 48%), supply chain planning (up 19 points to 35%), and process optimization (up 11 points to 36%).

The results show that manufacturing companies are moving AI from experimental applications to operations directly related to production performance. Companies are prioritizing AI use cases that impact throughput, planning accuracy, inventory management, and production efficiency.

Growing shortage of human resources

However, challenges are also emerging: 33% of respondents cited “lack of the right people” as a barrier, an increase of 8 percentage points since the last survey. Lack of cooperation between departments (31%) and resistance to change (24%) are also on the rise.

Interestingly, budget constraints and “lack of time to work on change” responses have decreased. This suggests that organizational readiness is replacing financial capacity as the primary barrier.

Economic Outlook and Investment Plan

The economic outlook for 2026 was cautious, with 31% expecting a decline in demand and only 19% anticipating growth. Tariffs and international trade instability emerged as major cost concerns, with 39% expecting raw material costs to rise due to tariff pressures and 37% planning price increases.

Still, 61% of respondents plan to increase spending on enterprise software in the next 12 months, with operations and production performance the top priority IT investment areas (40%).

Application to the Manufacturing Industry: AI’s Future

1. revolutionary reduction in manufacturing costs

Palmer Luckey, co-founder of Anduril, made a startling prediction in his February 4 talk. He claimed that AI will dramatically reduce manufacturing costs, stating, “Within our lifetime, we will be able to buy a car like the Ford F-150 for $1,000.”

In Luckey’s view, it is the conversion process and regulations, not the components themselves, that are primarily responsible for the current high costs, and he predicts that if the level of efficiency that AI automation has achieved in clothing and agriculture were applied to automobiles and home construction, the costs of resource extraction, processing, and manufacturing would approach almost zero. Furthermore, if recycling becomes possible at 90% efficiency, it will even be realistic to replace cars seasonally, according to the report.

2. widespread use of AI agents and IoT sensors

Cost-effective AI agents and IoT sensor technology are rapidly gaining traction, and according to Dot Ai CEO Ed Nabrotzky, “these devices are relatively inexpensive, and their technical capabilities have improved significantly in recent years.”

Autonomous monitoring of equipment, predictive maintenance, and supply chain management using IoT sensors is accelerating in the manufacturing industry, and according to a Deloitte survey, 46% of manufacturing companies are using IoT solutions to enhance visibility as they prepare for automation.

AI agents are software systems, such as large-scale language models, that can independently make decisions and perform multi-step tasks. In situations that “humans cannot effectively handle,” Nabrotzky notes that algorithmic decision-making brings greater efficiency and transparency to the marketplace.

3. response to cyber security risks

As the manufacturing industry handles more data and becomes more digitized, cybersecurity risks are increasing, and according to IBM’s X-Force 2025 Threat Intelligence Index, manufacturing has been the most targeted industry over the past four years.

In August 2026, Jaguar Land Rover suffered a $260 million loss when a cyber attack shut down production worldwide for five weeks. Also in October, Japanese beer manufacturing giant Asahi was forced to return to paper and pen after a ransomware attack.

According to the World Economic Forum’s 2026 Global Cybersecurity Outlook, 59% of the manufacturing, supply chain, and transportation sectors have adopted AI to enhance their cybersecurity capabilities. At the same time, 87% identify AI-related vulnerabilities as the fastest growing cyber risk, making balancing AI adoption and security measures a key challenge.

Implications for Japanese Companies

For Japanese manufacturers, the global AI trends of the past week contain important strategic implications.

First is the scale of AI investment. With U.S. companies investing tens of billions of dollars, Japanese companies must invest commensurately or risk losing their competitive edge in the use of AI technology. However, this does not necessarily mean that huge investments are necessary, but rather strategic investments in AI solutions optimized for their manufacturing processes are important.

Second is the global trend of “moving from pilot to implementation. While most Japanese companies are still in the proof-of-concept (PoC) phase of AI, global companies have already moved into the full-scale operation phase. To accelerate implementation, it is essential to have management commitment, cross-functional cooperation, and appropriate human resources.

Third is the use of physical AI and humanoid robots. Japan has led the world in the field of industrial robotics, but Western companies are ahead in next-generation robots with integrated AI; we need to accelerate the integration of robotics and AI technologies, as in the partnership between Boston Dynamics and Google DeepMind.

Fourth, investments in cybersecurity. As manufacturing sites become increasingly digitalized, the risk of cyber-attacks is rapidly increasing, and it is imperative to invest in AI-assisted security measures in tandem with the introduction of AI.

summary

The first week of February 2026 was a symbolic week as AI technology began to really penetrate the manufacturing industry: a massive $2.52 trillion global AI investment, the emergence of self-improving coding AI, the commercial deployment of physical AI and humanoid robots, and the “experimental phase to implementation phase” in manufacturing A clear transition from the “experimental to implementation phase” in manufacturing.

These trends indicate that the future of manufacturing is fundamentally changing: AI is more than just an efficiency tool; it has the potential to transform the very structure of manufacturing costs, redefine the collaborative relationship between humans and robots, and transform the way global supply chains are managed.

In order for Japanese manufacturers to remain globally competitive in the future, it is imperative that they accurately understand these technological trends and make strategic AI investments and implementations tailored to their own circumstances. The key to sustainable growth will be to position AI not as a “human replacement” but as an “amplifier of human capabilities.

Source List

- Manufacturers move from AI pilots to operations, execution in 2026 – Digital Commerce 360, February 2, 2026

- The State Of The $2.52 Trillion AI Bubble, January 2026 – Forbes, February 1, 2026

- Musk Inc. Billionaire combines his rocket and AI businesses – Broomfield Enterprise, February 2, 2026

- The physical AI craze and other automation trends to watch in 2026 – Manufacturing Dive, January 29, 2026

- Palmer Luckey says AI will make hardware so cheap – Fortune, February 4, 2026

- Introducing GPT-5.3-Codex – OpenAI, February 5, 2026

- Boston Dynamics partners with Google DeepMind on AI-driven Atlas humanoid – Waltham Times, February 3, 2026

- Alphabet resets the bar for AI infrastructure spending – CNBC, February 4, 2026

- AI Race Sends Big Tech’s Capital Spending to Stratospheric High – Bloomberg, February 6, 2026

- Humanoid Robotics Market in 2026 Transformative Trends – Yahoo Finance, February 4, 2026